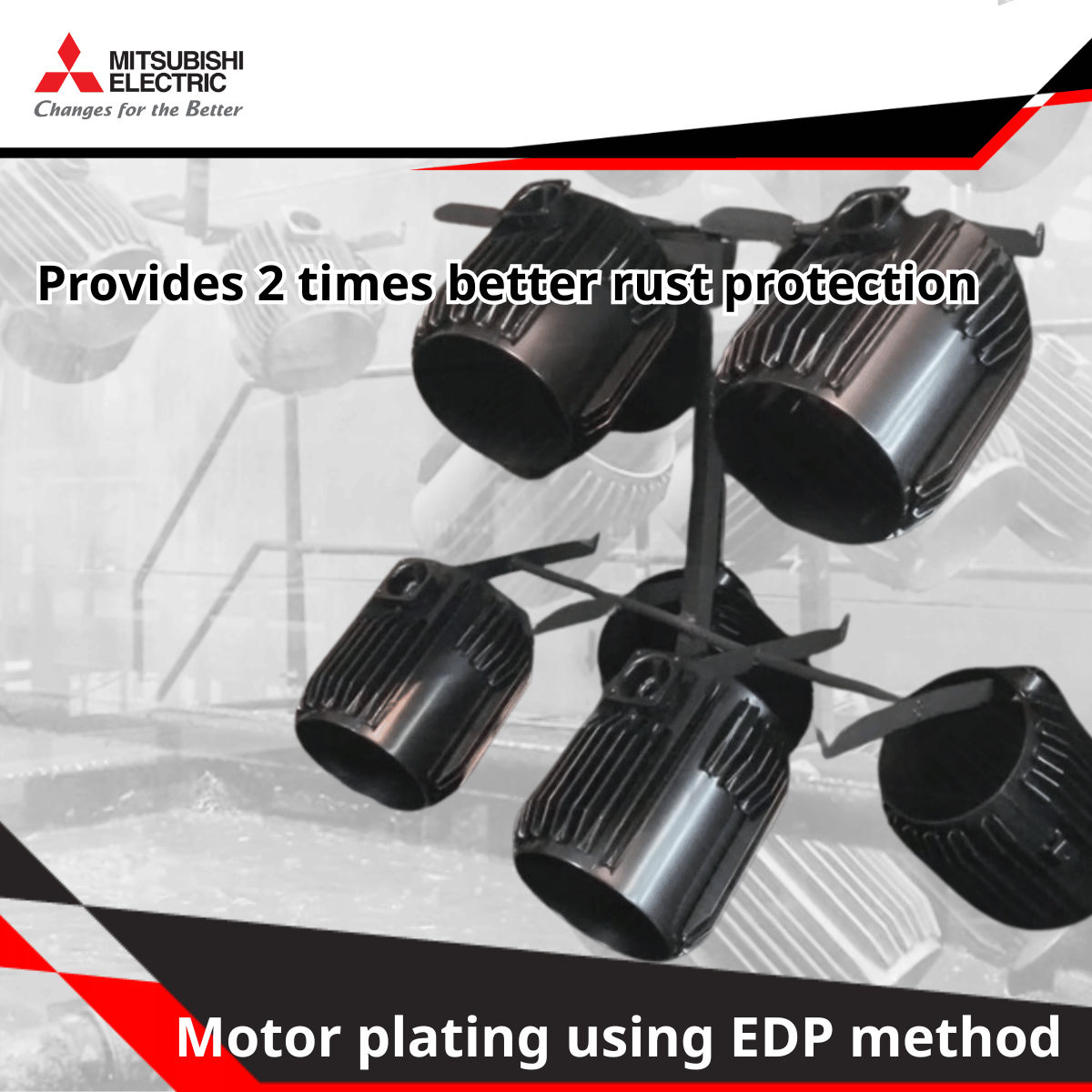

Motor plating using EDP method

Problems that users often encounter with conventional motor painting

Many people may overlook the importance of the surface coating process or motor painting, thinking that it is just a decoration to make it look beautiful. But in reality, motor painting with conventional methods often causes problems that affect efficiency, lifespan, and safety. To help you understand the importance of choosing the right surface coating method for your motor, this article will delve into common problems with conventional motor painting as follows :

- Corrosion : Poor or incomplete plating will expose the motor frame to moisture, chemicals, or corrosive environments, resulting in rust and premature deterioration, reducing the life of the motor. Some parts may be too thick or too thin, or there may be marks where the paint did not adhere, making it look unsightly and affecting the quality of corrosion protection.

- Reduced aesthetics : Uneven, stained, or easily peeling paint will make the motor frame look unsightly.

- Reduced Thermal Protection : Poor plating can reduce thermal protection properties, leaving the motor frame more susceptible to damage due to overheating, especially in heavy duty or high temperature motors.

These problems cause motors that are painted with ordinary methods to have a shorter lifespan, look unsightly, and are prone to damage. Therefore, choosing the right coating method is important to get a quality motor with a long lifespan.

So what is EDP motor plating?

EDP stands for Electro Deposition Painting or electroplating is a painting technique that uses an electric current to coat the paint on the surface of the workpiece. Using a paint solution that contains paint particles suspended in water or a solvent. This process uses an electric current through the metal parts, causing a chemical reaction and making the paint adhere to the metal surface thoroughly and evenly. It is a painting method that gives better results than the conventional painting method, especially for parts with complex shapes such as motor frames that require a complete and durable paint coating.

Advantages of EDP induction motor plating

- Durability : EDP-coated paint has high resistance to corrosion, heat, and wear, greatly extending the life of electric motors.

- Consistent and thorough color coating : EDP plating can coat the color evenly throughout the workpiece, including hard-to-reach areas such as grooves or corners, enhancing the beauty of the electric motor and helping to create a good image for the product.

- Save time and cost : The EDP plating process takes less time and is more cost-effective than other plating methods.

Overall, EDP induction motor plating is a technique that provides both aesthetics, durability and efficiency. It is suitable for motors that are used in conditions that require high durability and have strict quality standards.

“Easy to change, use it for a long time until you forget with EDP plating”

Mitsubishi Electric Motors are durable and have a long service life by using the "EDP structural surface coating process" which has higher adhesion than the general paint dipping method and prevents rust for 2 times longer than the previous type. It is resistant to corrosion and rust, so it saves on costs and does not need to buy new motors often.

Meet all your usage needs. Contact us to receive information and inquiries at

- 02-517-1326 Ext 301, 305, 306 (Sales)

- Line ID : @motor.meath

- Faceboook : มอเตอร์ไฟฟ้า มิตซูบิชิ

Ready to provide advice and professional after-sales service

- Line ID : @service.meath

- Order Motor and Pump spare parts Line ID : @shop.meath

- Tel : 02-906-3337, 02-906-3338

Office and Factory

Mitsubishi Electric Automation (Thailand) Co., Ltd.

Bang-Chan Industrial Estate, 111 Soi Serithai 54 T. Kannayao, A. Kannayao

A. Kannayao, Bangkok 10230, Thailand

Tel: (66) 2517-1326, (66) 2919-9873