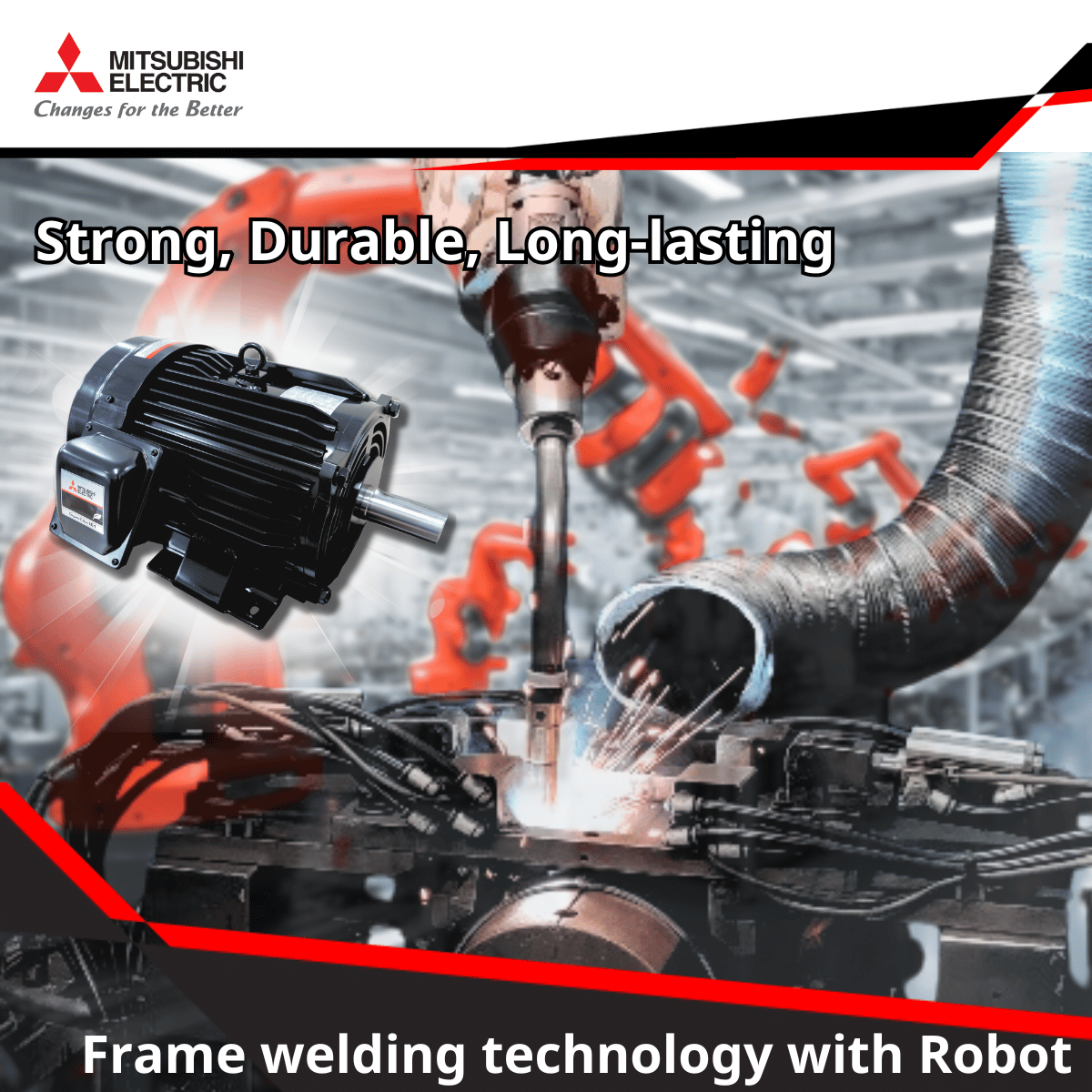

Frame welding technology with Robot

Strong, durable, long-lasting with Robot frame welding technology

In an era where technology drives production, robots are introduced into various processes.

This is especially inevitable in the welding of motor frames, which is a critical process that requires high precision and consistency in production. Robot welding of motor frames is superior to traditional manual welding in the following ways :

- High accuracy The robot is capable of moving and positioning welding with high precision, reducing the possibility of errors that may occur from inconsistency of human labor.

- Superior production efficiency The robot can work continuously without fatigue and without stopping, allowing the production of motor frames to proceed quickly, increasing production volume and reducing production time.

- Consistent quality The robot can repeat the welding process precisely every time, resulting in consistent weld quality and reduced product variability.

- Reduce labor costs Using robots can reduce human labor in the production process, helping to reduce labor costs and overall production costs.

- Easy to customize The robot's operating program is easy to customize, allowing it to support the production of a variety of motor frames, and the changes in the design can be quickly adapted to changing needs.

What are the problems caused by poor motor frame welding ?

A poorly welded motor frame may seem like a minor issue, but the consequences can be serious, ranging from malfunctions, noise, to potential damage. To understand the importance of welding a motor frame, let’s take a look at some of the problems caused by poorly welded motor frames.

- Reduced performance : Poor welding of the motor frame may cause the structure of the motor frame to be weak, causing vibration or abnormal noise during operation, resulting in reduced performance of the motor, which may not work efficiently or be easily damaged.

- Overheating : If the welding is incomplete, it may cause a weak connection point and excessive heat build up in that area, which may damage the motor insulation, cause a short circuit, or even burn out the motor.

- Shorter lifespan : Poorly welded motor frames are less durable. The structure is easily damaged by vibration or impact, resulting in a shorter motor lifespan, more frequent maintenance, and increased maintenance costs.

Robotic motor frame welding is an important technology to enhance production capabilities, resulting in high-quality products. Therefore, it is a worthwhile investment for businesses that want to enhance their competitiveness and respond to market demands effectively.

"We use advanced technology to create high-quality products for you"

Mitsubishi Electric Motors have a strong and durable motor structure from Robot frame welding technology Robot , which makes the welds of the structure more detailed, consistent, and integrated than general motors that use manual welding, helping to extend the service life and reduce maintenance costs.

Meet all your usage needs. Contact us to receive information and inquiries at

- 02-517-1326 Ext 301, 305, 306 (Sales)

- Line ID : @motor.meath

- Faceboook : มอเตอร์ไฟฟ้า มิตซูบิชิ

Ready to provide advice and professional after-sales service

- Line ID : @service.meath

- Order Motor and Pump spare parts Line ID : @shop.meath

- Tel : 02-906-3337, 02-906-3338

Office and Factory

Mitsubishi Electric Automation (Thailand) Co., Ltd.

Bang-Chan Industrial Estate, 111 Soi Serithai 54 T. Kannayao, A. Kannayao

A. Kannayao, Bangkok 10230, Thailand

Tel: (66) 2517-1326, (66) 2919-9873