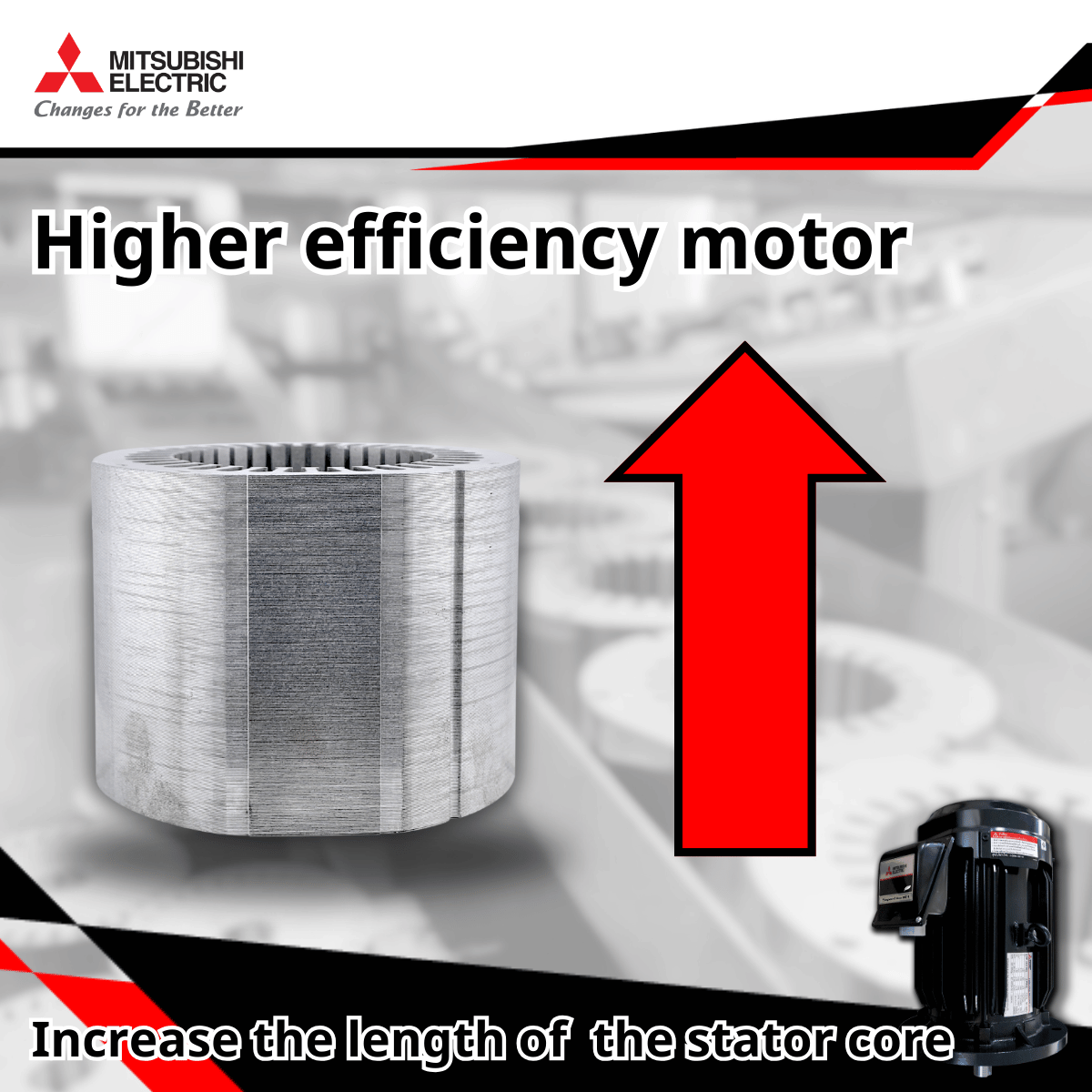

Increase the length of the stator core

Increase the length of the stator core

The Stator Core may seem simple, but small problems with this part can cause unexpected damage to your motor. Let’s take a look at what those problems are and how to prevent them.

What are the common problems encountered with the Stator core?

- Improper Design Improper design such as size, shape or materials used will affect the efficiency, torque and performance of the motor. It may cause the motor to not work at its full potential or be damaged. Therefore, choosing the right materials and design is important to achieve the best efficiency.

- Manufacturing Errors Manufacturing errors such as incorrect assembly, incorrect forming will cause vibration, noise and reduce the efficiency of the motor. Therefore, quality control in manufacturing is essential to ensure that the Stator iron core is of good quality and meets the standards.

- Material quality : Using low-quality or substandard materials will reduce the strength and durability of the Stator core, may break or be easily damaged, and reduce the life of the motor.

It is important to select high-quality materials to ensure that the Stator core is durable and can be used for a long time.

The effects of these problems, problems with the Stator core will result in reduced motor efficiency, higher energy consumption and susceptibility to damage. It can also shorten the motor’s lifespan and increase maintenance costs. In severe cases, it can cause danger to the user.

So how canwe prevent this problem? ?

Selecting quality materials, proper design and quality control in production are very important to prevent problems that may occur with the Stator Iron Core. Although the Stator Iron Core is just one component, it plays an important role in the operation of the motor. Attention to detail and good selection of materials and manufacturing processes will help ensure that the motor will work efficiently and have a long life.

Increase the length of the stator core

The “Stator iron core” is wrapped with copper wires. When an electric current flows through it, a magnetic field is created. This magnetic field reacts with the conductors in the rotor, causing the motor to rotate. The Stator iron core uses a complex design, which directly affects the efficiency, torque, and various performance of the motor. This article will take you to explore the “Stator iron core” Stator” , what its function is, and how its design affects electric motors.

Stator Core Design

- Structural design : Improving the structure of the Stator iron core, such as increasing the number of iron sheets and adjusting the shape of the iron sheets, can reduce the magnetic field loss and reduce the heat generation inside the Stator iron core.

- Selection of coating materials Selection of appropriate coating materials can reduce magnetic field losses and heat generation within the stator core.

Benefits for clients' businesses

- Improved motor performance The design of the optimum stator iron core can improve the efficiency of electrical energy conversion into mechanical energy, make the motor work more efficiently, reduce energy loss, and save electricity in the long run, which can reduce operating costs.

- Higher torque The well-designed stator iron core increases the motor torque, allowing it to be used in machinery and equipment that require torque, increasing production efficiency and reducing working time.

- Longer life The strong and durable design of the stator iron core extends the life of the motor, reduces the frequency of maintenance, and reduces the cost of replacing parts, which reduces operating costs and improves product reliability.

- Reduce production costs Proper design of the stator iron core will reduce the amount of materials and energy used in production, thus reducing global warming.

The stator iron core with the right shape, material and size will improve efficiency, reduce energy loss and increase torque. The development of manufacturing technology and materials will make the stator iron core more efficient and energy-saving, making the electric motor more efficient and environmentally friendly.

Mitsubishi Super Line Q Series motors have a"new" design of the stator iron core, reducing the loss in the iron core (Iron Loss) by changing the grade of iron used in the production to help reduce electromagnetic losses.

Meet all your usage needs. Contact us to receive information and inquiries at

- 02-517-1326 Ext 301, 305, 306 (Sales)

- Line ID : @motor.meath

- Faceboook : มอเตอร์ไฟฟ้า มิตซูบิชิ

Ready to provide advice and professional after-sales service

- Line ID : @service.meath

- Order Motor and Pump spare parts Line ID : @shop.meath

- Tel : 02-906-3337, 02-906-3338

Office and Factory

Mitsubishi Electric Automation (Thailand) Co., Ltd.

Bang-Chan Industrial Estate, 111 Soi Serithai 54 T. Kannayao, A. Kannayao

A. Kannayao, Bangkok 10230, Thailand

Tel: (66) 2517-1326, (66) 2919-9873